New concepts in the traditional metal-casting town of Takaoka

Perhaps because trees cover more than two-thirds of their country, Japanese craftsmen are most familiar with wood as a medium. Their long experience and history of innovation have elevated Japanese woodcraft to the highest level in the world. Though they may be fewer in number, Japan’s metal crafters are equally skilled, producing an impressive array of metalwork from traditional handcrafted swords and knives to delicate gold leaves as thin as a ten-thousandth of a millimeter. Rooted in these remarkable traditions, the Japanese metal industry is now taking on a whole new look with the use of unconventional materials and designs.

Our story begins with the town of Takaoka in Toyama prefecture, which has a metal-casting industry going back 400 years. The streets of the town are lined with wholesalers and workshops, selling items ranging from statues and temple bells to tea utensils and handicrafts. Copperware from Takaoka comprises more than 90 percent of that sold in Japan. While other towns also produce copperware, what sets Takaoka apart is the remarkable techniques used by the town’s artisans for casting nearly every kind of metal—from gold and silver to iron, tin, and titanium.

With lifestyles changing, the demand for such traditional wares as Buddhist altar fittings and temple bells has been declining steadily in recent years. But Takaoka is now seeing an upsurge of metal designs in tableware and interior items, which are making inroads into modern urban life. At the forefront of this new trend is Nousaku Corporation, one of Takaoka’s preeminent metal casters. "We had no idea what the market for our products was, because we’d been selling through wholesalers back then. To change the course of our business, we started off by launching new designs and marketing them outside Toyama prefecture," says Katsuji Nousaku, the company’s president.

One of the early efforts, brass bells designed by Nousaku himself, were selling poorly. A shop assistant setting the bells out for display said, "They make such beautiful sounds. How about turning them into wind chimes?" It was an epiphany: when the Nousaku bells were marketed as wind chimes, they sold like hotcakes. Since that episode, Nousaku has made it a rule to seek out the opinions of shop attendants who sell his products, to actively hire outside artists, and to approach product development with an unfettered, free-thinking spirit.

A good example is his attempt to make items from 100 percent pure tin, a metal known for its antimicrobial activity. The challenge is that unalloyed tinware bends easily when handled with force. For it to be stronger, it must be made thicker, but that drives up the material costs, which then raise product prices. After agonizing over the conundrum for six months, Nousaku was finally inspired by one of his designers, who said, "If it bends, why not let it bend?" Nousaku turned the extreme pliability of pure tin to his advantage in creating the "Kago" series of metal baskets, which can be bent by hand into any shape the user desires. The trailblazing series has become a great success, overturning the common preconception of metal as a cold and unyielding material.

The awe-inspiring spectacle of metal emerging from sand

Employees hard at work in the Nousaku factory.

At the Nousaku factory in Takaoka’s Toide Industrial Park, the young workers are toiling away: here, anyone over forty is considered old. Nousaku uses traditional sand molds for its metal castings. The metal-casters, some of whom are women, are covered with sand as they make molds. It is a delight to watch the deft movements of their fingers as they move with the grace of skilled craftsmen. The younger Nousaku employees all yearn to be casters.

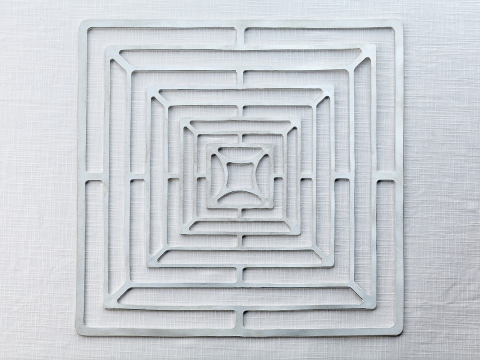

Casting is a metal-crafting method that involves pouring molten metal into a mold, letting it cool, and then removing the finished cast from the mold. First, a mixture of casting sand and clay is pressed around a pattern of the object to be produced, which is placed in a rectangular metal or wooden framework. The sand mixture is thoroughly tamped down with a tool or with hands and feet. Next, the pattern is removed from the packed sand, which is separated into top and bottom molds. The surface of both sand molds is coated liberally with white powder, a release agent that prevents metal from sticking to the molds. Then a core called a nakago, made from a negative form of the original pattern, is inserted between the top and bottom molds to create a space. Molten metal is then poured into the three-part sand mold – top, middle (core), and bottom – to flow through a narrow canal built into the mold. The more complex the shape of the finished product, the more intricate the sand mold and canal have to be. The canal must be built into the sand mold with absolute precision, which requires skilled craftsmanship. If the canal is not perfectly formed, the molten metal will not penetrate the sand mold as evenly and thoroughly as it should.

The casters are releasing molten alloy from the smelting furnace.

After checking its temperature carefully, the casters pour the red-hot molten alloy through the mouth of the canal into the sand mold. To an onlooker, the molten metal seems to be disappearing into the box, but the casters can no doubt clearly visualize the scarlet liquid metal flowing through the canal and penetrating deep into the nooks and crannies of the sand mold.

As soon as the metal has set and cooled down, the casters break open the mold. A brass piece emerges, streaked with black sand grains and dimly shining in gold. There is something awe-inspiring about the glimmering brass; it brings to mind the moment when the moon breaks through the clouds on a dark night. The sand mold has left the surface of the work rough to the touch. It can be left as it is, with an interesting grainy texture, or polished until it gleams.

Nousaku has been presenting its new products at such international trade expos as "Maison et Objets," constantly setting the bar for new metalwork trends overseas. "It’s not enough to have a famous designer," says Katsuji Nousaku. "Making good products takes close collaboration between designers, craftsmen, and salespeople. Our products must be invested with both tangible and intangible qualities, as well as the passion of their creators. I want to make the most of our history, culture, and traditions, and draw strength from them as I work."

Nousaku tableware, born from an auspicious union of craftsmanship, skills, and spirit, is nurtured by strong local traditions and innovative designs.

![[Sheep] “Eto” pure tin sake cup](/upload/save_image/12251710_549bc6737952e.jpg)

Metal a la mode (front cover)

Metal a la mode (front cover)  Kitchen Tools from Metalworking Mecca of Tsubame-Sanjo

Kitchen Tools from Metalworking Mecca of Tsubame-Sanjo  Hammered-metal artist--Jun Tanaka

Hammered-metal artist--Jun Tanaka